|

||

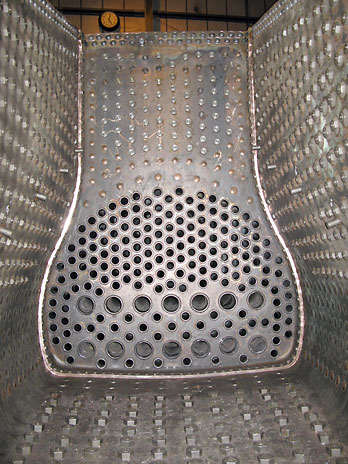

NewsMarch 2013After a steady spell in service during the last autumn in early December the loco was failed after a regular washout exam. A crack was found in one of the main steam pipes between the regulator and the superheater header. Over the closed season sources of new pipe work have been established but given the long lead time temporary repairs have been carried out allowing the loco to re-enter service on Saturday 2 March. The photo below shows 2857 pulling away from Bewdley North's up home signal with the 10:25 service from Bridgnorth on the 2 March. August 2012 - Valve Failure2857 suffered a severe valve failure on the evening of Friday 7th August 2012. On approaching Arley in the ‘up’ direction the valve events started to become uneven. Upon reaching Arley the driver (Duncan Ballard) examined the locomotive. No external defects were found during this examination and so he continued on his journey. On leaving Bewdley the locomotive was found to be very ‘off-beat’ and Duncan decided he was going to fail the locomotive on arrival at Kidderminster. However he never got there before total failure of what is now known to be the Left hand front valve head. On his approach to Kidderminster Duncan opened the regulator and all that was heard was a continuous roar up the chimney. The train continued rolling until the locomotive could no longer move the train and stopped, resulting in the train being rescued by the 08 diesel shunter. It is fair to say that Duncan took all the correct options open to him at the time, with this being a very quick deterioration in locomotive performance. After towing the dead loco back to Bridgnorth the SVR stripped the valves and examined the pistons to ascertain what had happened. The left front valve head had smashed, damaging all components for that valve head. The rear valve head was intact and free from damage, as were the right hand valves and both pistons. The cause of failure remains rather open to conjecture. The only part found to be missing from the valve head was the taper pin that goes through the nut holding the front valve in place on the spindle. This may have worked loose resulting in the nut becoming loose, allowing the valve head to travel up and down the valve spindle until the valve head smashed. No evidence could be found of the taper pin coming out of its hole before or during the events, so all that could be done was to surmise as to the causes. All the other taper pins were found to be secure. A new valve was manufactured in the Bridgnorth workshop in commendably quick time and 2857 returned to traffic on Monday 20th August 2012. July 2012 - BoilerAfter quite a few attempts to rectify some very silly leaks which should not have occurred, the decision was taken on 20th April 2012 to lift the boiler out of the frames. The decision to remove the boiler from the frames was a hard one to take by Works Manager Ian Walker and the new Boiler Shop Manager Duncan Ballard, but the findings justified that decision. Once the decision had been made, our volunteers assisted with the preparation work for lifting the boiler. The boiler was out on the floor by the following Wednesday. Duncan commented that it was nothing serious, more an irritation, though to us it represented an intensely frustrating disappointment. The throatplate patches have been leaking since the boiler was commissioned last year and were showing no sign of settling down. Whilst the boiler was out we re-caulked some stays and replaced others in the fire area which have also been giving intermittent leaks. As with the main overhaul the work has continued as a joint paid staff/supervised volunteer effort. It was while cleaning out the water space between the copper and the steel fireboxes, down near the foundation ring, that we made the most serious discovery – an old scrapped stay from the 1985 to 1995 boiler certification had somehow survived all the turning over, foundation ring out, firebox sides off, copper tubeplate out, and yet still remained inside the boiler. Unknown to anyone it had then slipped down inside the water space to lodge vertically sitting on the foundation ring and causing a blockage to the removal of solids deposited in the boiler. It was only found when we removed the otherwise inaccessible stays normally hidden behind the frames and then discovered excessive scale built up around each stay position. It was extremely fortunate that we found this problem, as if left unattended the copper firebox plate would have become overheated with only solid immovable scale deposits behind it instead of water, and become distorted, scrapped or worse. So in a way we feel that the cloud of having to attend to the boiler so early on has had a silver lining in finding this problem before it became serious. This re-working of 2857’s boiler on 2857 is unheard of on any other in the Railway’s history, especially so early in a boiler’s life, and at this stage no-one is trying to apportion blame. Ian Walker stresses to all of us doing the boiler work that the problems on the boiler were in no way a reflection on the skills and abilities of those involved. All our volunteer work was supervised by the SVR, while all boilers have to pass hydraulic and steam tests before fitting to the frames and this boiler passed those with flying colours. It has been suggested that the rigours of varying pressure cooling and heating, vibration and so on soon showed up the weaknesses that won’t show on static tests, but then again the same rigours would be present on every other boiler sent out by the boiler shop, yet without showing the same levels of trouble. It appears that the SVR had a number of issues around the time of this overhaul which have since been dealt with by appropriate corrective actions.

January 2012 - Valves and Back CoversIn mid December 2011 No. 2857 was believed to have suffered a 'hydraulic incident’, ingesting water behind both pistons but not, curiously, in front. Once 2857 had finished her 2011 ‘Santa’ duties it was decided to strip her down at the front to investigate this area and we made a start on 21st January 2012. Dave Reynolds asked us to remove and visually examine both the left and right piston valves for cracks or obvious deformity. We needed all parties to bear in mind the special stud/integral port bar which we had installed back in 1984 to give added support across the one small crack we found in the Briton Ferry block, at the ‘2 o'clock’ position on the LH front cylinder cover. This stud extends beyond the face of the nut and has two flats which need to be held with a spanner when tightening/untightening this particular nut.

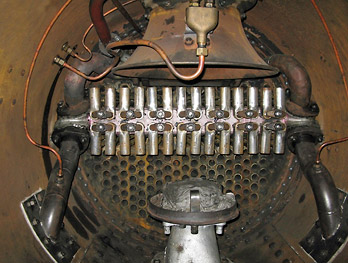

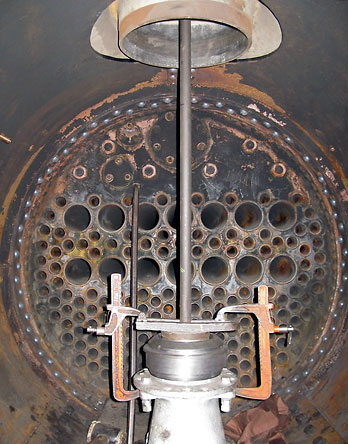

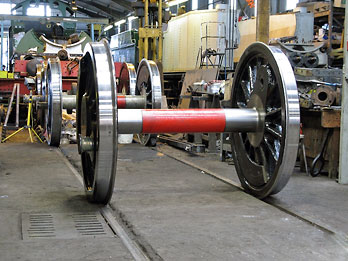

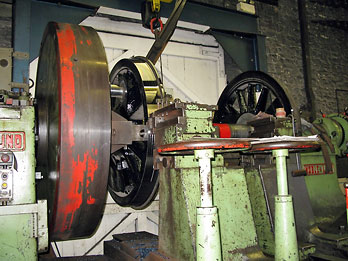

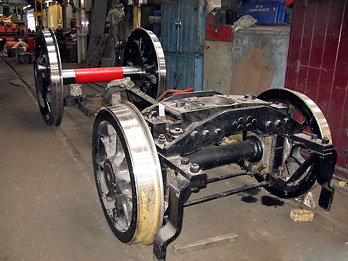

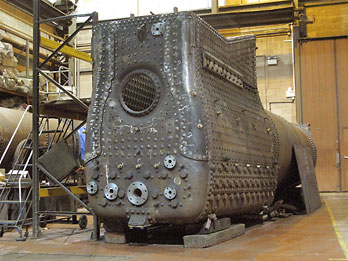

On stripping it down we noticed that the right hand steam chest was full of water. On further investigation we discovered that the pipe connecting the steam chest to its drain cock was completely blocked. The blockage on the left hand side drain was largely due to a lump of weld spatter, about 35mm long x 12mm diameter, too big to get round the bottom bend in the pipe. 18th May 2012A new photo Gallery for 2012 has been added. 31st August 2011A new photo Gallery for 2011 has been added now 2857 has returned to service. 23rd August 2011On Wednesday the 17th August 2857 was pressed into service following repairs needed after 9 days of initial running in. The following photos were taken over the succeeding weekend. 20th August 2011 – Being prepared for the day’s service 2857 stands over the pit at Bewdley with 7812 Erlestoke Manor on the adjacent road. 20th August 2011 – 2857 north of Bewdley making light work of the 9 coach load forming the 10:35 Kidderminster to Bridgnorth service. 21st August 2011 – 2857 stands at Bewdley platform 1 on the 15:35 Kidderminster to Bridgnorth service. 2857 is now back in daily service for 28 consecutive days starting last Saturday (20th). She is working from Bewdley shed (ie trains starting from Kidderminster), the normal pattern being alternating - one day working the first departure, then the next day the second etc. 28th July 20112857 is also running on Sunday this weekend (the same diagram; 10.55 from Bridgnorth). It will then out of traffic from Monday onwards for boiler washout and attention to any minor repairs arising from this weeks running. 25th July 20112857 is booked to work service trains on the SVR today (25th) and every day this week and including Saturday, as follows: Saturday: She worked in tandem with 4566 the same two trips last Thursday (on the first returning trip a drain cock stuck open with slag, which was easily removed/cleared on arrival at Bridgnorth, otherwise no other faults) and worked these two trips again solo on Friday without incident. 22nd July 2011And two further shots of yesterday's run. Photo by Tom Clarke 21st July 2011 update2857 double heading with 4566 at Hampton Loade 21st July, in charge of the 13.00 Kidderminster - Bridgnorth - its first round trip passenger turn since 1994! Photos: John Oates 19th July 2011 updateFollowing final assembly and static tests we are pleased to report 2857 has been out on the line for further testing. Although all's not as may appear here at first glance - as 9F 92212 is propelling 2857 back to Bridgnorth for repairs to the front section of the grate. Photographed at Hay Bridge by Bob Sweet. 23rd May 2011 news updateOn the 19th May 2011 superheater elements for 2857 were delivered. On Saturday 21st May they were fitted. 21st May 2011 – 14 new superheater elements 21st May 2011 – Inside the smoke box with all 14 elements fitted. 10th May 2011 news updateOn the 6th May 2011 2857 was shunted out of the paint shop at Bridgnorth and reunited with the tender. The following views show 2857 in the main shed. 7th May 2011 – Front ¾ view 6th May 2011 – Rear ¾ view, coincidentally the trailing axle of the tender is over the wheel drop 6th May 2011 – Close up of the front buffer beam 6th May 2011 – Close up of the cab side 6th May 2011 – Close up of the front ash pan discharge door. April 2011 news updateWork is progressing steadily as the two following views show. 9th April 2011 – The smokebox with only the superheater elements to go in. 16th April 2011 – The majority of the paintwork is now finished. March 2011 news updateThese two views illustrate some of the work that has been carried out over the last 3 weeks. 5th March 2011 – The cab looking much more complete with the majority of the pipe work done, gauges, whistle chains, sanding gear, and ATC box fitted. 5th March 2011 – View of the front of the cab. The holes for the “porthole” windows have been blanked off in keeping with the livery period. The whistle bracket was originally fastened directly to the boiler, however the resulting hole in the cladding allowed water to run into the lagging. Therefore the arrangement has been modified by placing a rectangular plate over the hole and fastening the bracket to it. February 2011 news updateThe loco was moved into the paint shop at Bridgnorth in late January where work on the assembly and painting of the loco has continued. 13th February 2011 - In the paint shop with injectors and feed pipes fitted, boiler cladding now complete, including injector feed pipe covers, and safety valve bonnet. Note also the main steam pipes from the smoke box to the valve chests, cylinder block cladding and freshly painted butterfly plate. 13th February 2011 – View of the cab. 13th February 2011 – Inside the smoke box, with the superheater header and regulator valve fitted and main steam pipes located in position. 13th February 2011 – Given the time that the loco has been out of traffic remarkably few pieces have been lost. One part that had gone missing was a section of channel linking the spectacle plate to the fire box top cladding sheet. A new piece has been made shown here “ready for paint”. January 2011 news updateWork has been progressing steadily with the assembly of the loco. 15 January 2011 - The boiler cladding is nearing completion. 15 January 2011 – Front ¾ view showing progress on the smoke box. 15th January 2011 – The cab is taking shape with backhead cladding; sight feed lubricator, fire hole doors, spectacle plate and the roof fitted. 18 December 2010 – Positioning the chimney above the re-fitted blast pipe. Note the ring of new rivets fastening the smoke box to the boiler barrel. News update November 2010Major progress has occurred over the last six months culminating in the latter part of October and early November with the loco re-wheeled and re-united with its boiler. 20 November 2010 – The boiler fitted to the frames. 20 November 2010 – Another view of the boiler back in the frames. 20 November 2010 – The new ashpan fitted to the firebox 19 November 2010 – 2857 emerged from Bridgnorth shed. 19 November 2010 – waiting to be shunted into the boiler shop. 19 November 2010 – a second view outside the boiler shop. 19 November 2010 – Another view outside the boiler shop, note the boiler door plate now sooted up from the successful steam test earlier in the week. 13 November 2010 – 2857’s boiler outside the boiler shop having been sand blasted and painted during the previous week. 13 November 2010 – a second view outside the boiler shop. 29 October 2010 – 2857’s boiler under test in Bridgnorth yard at full working pressure of 225lbs/in2 with the safety valves feathering nicely releasing excess steam. 29 October 2010 – This view was taken a few days after 2857 had been re-united with its wheels. Note the new blower ring and petticoat pipe in the foreground. 28 August 2010 – 2857’s boiler under test alongside visiting GW 2-8-0 number 3802. Note the regulation light grey haze from the smoke box. 28 August 2010 – The first fire for nearly 16 years! 24 July 2010 – Wheel sets after tyre turning. 17 July 2010 – Completed axle box. 17 July 2010 – Axle box part way through machining. 17 July 2010 – Re-metalled axle boxes awaiting machining. 17 July 2010 – Completed crossheads. 3 July 2010 – Coupled wheel set on the lathe. 3 July 2010 – Re-assembled pony truck with completed coupled wheel set behind. News update May 2010The boiler repair is now complete. The accompanying photos show the boiler outside the boiler shop for the first time in 6 years marking the end of a heavy repair mostly carried out by 2857 Society volunteers, closely supervised by the Severn Valley Railway's boiler shop foreman. Testing and certification will be carried out nearer to completion of the mechanical overhaul currently progressing well in the Bridgnorth workshops. News update February 2010 The following photographs show the boiler on the 30th January 2010. The boiler repair is now substantially complete. News update Jan 2010Two photos from Des Ainsworth of 2857's freshly painted tender, taken 10th January while it was briefly outside. Splendid! Previous NewsNews from 2007

|

Website updatesMarch 2013 31st Aug 2012 14th Aug 2012 18th May 2012 31st Aug 2011 23rd Aug 2011 25th & 28th July 2011 19th, 21st & 22nd July 2011 24th May 2011 12th May 2011 19th April 2011 7th March 2011 17th Feb 2011 17th Jan 2011 26th Nov 2010 10th Feb 2010 8th Feb 2010 19th Jan 2010 2nd June 2009 28th April 2009 22nd April 2009 26th Jan 2009 16th Dec 2008 17th Nov 2008 2nd Sept 2008 8th July 2008 9th June 2008 6th June 2008 26th March 2008 6th February 2008 10th December 2007 25th October 2007 13th September 2007 25th July 2007 8th March 2007 15th January 2007 10th January 2007 21st September 11th September 25th August 17th July 20th April 2006 |

© 2857 Society 2007-2022