|

||

News

Boiler Overhaul - July 2006

All the steel side stays fitted last month have been caulked inside and out and nuts fitted on the inside (these protect the ends of the stays). Some of the copper side stays have been riveted over.

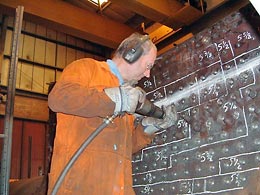

Caulking steel sides stays. This operation involves hammering the plate work into the stay using a pneumatic hammer with a semi circular tool to form a steam tight seal around the stay. This operation is carried out on both the inner and outer plates of the firebox.

Riveting copper side stays to form a steam tight seal.

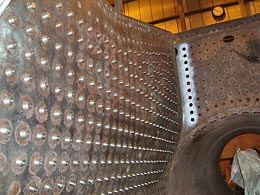

Stay nuts fitted to the left hand side of the firebox (the boiler is upside down in this view)

Work has also been carried out on the throat plate (the front section of the firebox, under the boiler barrel). This has involved grinding out cracks on the outer row of stay holes to evaluate the extent of the damage.

The testing kit consists of a hand held electro magnet. The area to be tested is sprayed with white paint to maximise the contrast with the black marker ink which is applied with the electro magnet energised.

Marker ink has been sprayed on and drawn into the cracks by the magnetic force. The two poles of the electro magnet are on either side of this view.

Close up of the cracks. These have now been ground out.

Boiler Overhaul - April-June 2006

Work on 2857's boiler over the past two months has progressed very well in spite of a significant setback due to theft of some of our new parts in May. We have now fitted all the stays that can be at this stage. The remaining ones will be fitted once the new firebox tube plate is fitted and repairs to the copper door plate are complete.

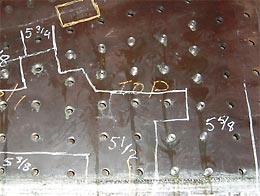

This view shows the drivers side of the firebox with new steel side stays fitted and 'set' to have the correct length protruding beyond the surface of the plate work. The white area is on the throat plate (the front section of the firebox under the boiler barrel) where we are identifying cracks between the outer rows of stay holes. These cracks will be ground out and welded. The holes appear rather large as the bushes have been removed so new ones can be fitted to allow us to fit minimum diameter new stays.

Fitting steel stays into the door plate.

Fitting copper stays on the left hand side of the firebox.

Cutting stays to length ready for riveting.

Work has also been going on at the front of the boiler barrel. The section of barrel that the smoke box fits onto was badly corroded. The effected area has been removed, a new section made and prepared for welding. This brief description doesn't do justice to the extensive work involved.

The front section of the boiler barrel before work started, note the knife edge appearance illustrating the extent of corrosion. This is a common defect.

This view shows the front lower section of boiler barrel with the corroded section removed.

Repair section ready for welding

Boiler Overhaul - Easter 2006

The first of new copper side stays have been annealed and as many as possible of the steel ones were fitted over Easter.

New Side Stays

First new side stay being fitted

An area on the left hand side of the firebox where new stays have been fitted. The markings refer to the length of stay, those fitted being 5 5/8" long. This is a new section of outer wrapper, the weld fixing the repair section in place is at the bottom of the photo.

Another job that was completed over Easter was the removal of around 30 countersunk bolts fixing the copper door plate to the side sheet. This has been done to facilitate weld repairs to the flanges. The process consisted of chiselling off the heads of the bolts (carried out the previous weekend), drilling out the centre of the bolt and then finally chiselling out the remainder.

Drilling out the centre of one of the bolts fastening the copper door plate to the side sheet. The boiler is upside down with the doorplate on the left of the photo, the adjustable spanner is sitting on the foundation ring.

© 2857 Society 2007-2009