|

||

News - 2008

News update December 2008

2857 was moved from Bewdley to Bridgnorth on Monday 8th December, thanks to all those involved. These views were taken on Saturday 13th December showing 2857 standing alongside the jacks in the loco shed. The tender will be moved onto the jacks shortly for mechanical work, followed by the loco.

News update November 2008

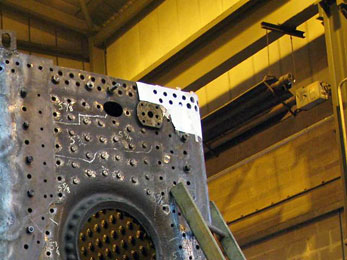

Since the last update we have fitted all the foundation ring rivets other than those that go through the door plates patches.

New rivets on the right hand side of the foundation ring.

New rivets on the front left hand corner of the foundation ring, note the corner rivet where the snap head has been riveted down to fit the corner radius.

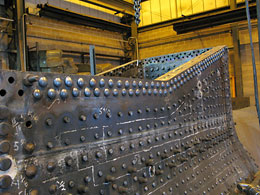

Tooling up and caulking the foundation ring rivets.

Trial fitting of the smoke box spacer ring.

Whilst the previous photograph showed that the spacer ring needed some persuasion to get it into place there was however once in place it was clear that there was some minor modification needed.

This view shows a small gap which we had to close up by heating and modifying the barrel extension.

After modification.

The new front ring for the smoke box delivered recently.

News update September 2008

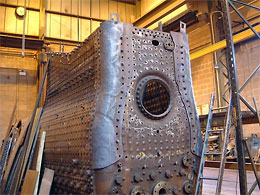

Work over the past two months has been mostly concentrated on the door plate patches. This has involved detail trimming and fitting work.

Template for marking out foundation ring holes on the left hand door plate patch. The holes are cut in the template, the template was then used to mark out the hole positions on the patch.

Drilling the foundation ring rivet and stud holes in the left hand door patch.

This view shows the left hand patch in place with the foundation ring rivet and stud holes completed. Note that the right hand patch has been removed for further work and that there are pieces of string on the bolts. As we have needed to take the plates off and refit several times the strings help to refit the bolts on each occasion.

This view shows the weld prep where the patch meets the side wrapper.

The barrel extension repair has been completed, fitting the tube plate allowed the welding to be completed and we have now also drilled the holes for the smoke box connection.

Another more minor job completed recently is shown here. The new studs have been fitted where the ejector support brackets have been removed. These brackets are not needed for 2857 as the ejector exhaust is via an internal pipe.

The first foundation ring rivets have been fitted. These are on the left hand side of the firebox.

This shows the same rivets but viewed from the inside of the firebox.

News update June 2008

On Saturday the 7th June the new smoke box tube plate was fitted into position. The work was carried out by members of the Society’s engineering team and the SVR’s Boiler Shop Foreman. The work went reasonably smoothly with some gentle persuasion firstly with a large hide mallet and latterly with our “small” tupping bar hanging from the overhead gantry crane. In spite of one member of the team tempting fate by commenting that “we should get this done by lunchtime” we did indeed do so, leaving time in the afternoon to start the job of reaming the rivet holes.

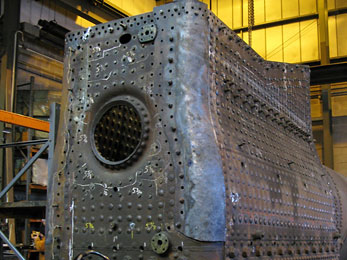

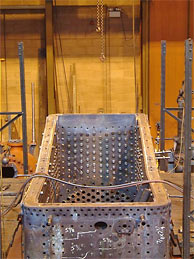

The new tube plate in position. Note that the boiler is upside down.

Reaming the rivet holes.

News update May 2008

Some 16 patch screws have been fitted on the two front corners of the foundation ring.

Patch screws on front corner of foundation ring. Note the new stays visible through the repaired mud hole door.

We have now moved onto work on the two door plate patches. These were rough formed a while ago but we needed to have the foundation ring in place before the further work could progress. Excess material was trimmed from the patches and then they were reattached to the door plate for further fitting work as illustrated in the following photographs.

To ensure the patch is firmly fixed to the boiler bolts were fitted from the water space. As it is impossible to reach in and place these bolts so they are threaded in using twine. Two methods can be used, the first illustrated in this and the next photo involve dropping a string line from the hole through which the bolt is to be fitted down to a washout plug hole where the bolt is then tied to the line and pulled up through the water space.

Bolt in position ready for nut and washer.

The alternative method involves threading the twine up through the stay holes to pull a bolt up through the water space to where it is needed.

With the patches firmly bolted to the door plate fitting work could then continue. This involved heating the patch in a fairly localised area and then hammering it down to get a closer fit to the boiler plate. The following photographs illustrate the process.

Heating an area of the patch

With the area of the patch red hot, the plate is hammered down.

Heavy work so it’s best to take turns. Note the scotchman and wedge just below the heated area. This is a temporary bracket welded to the side of the boiler, the wedge then stops the plate lifting as it cools.

Having found some suitable scrap steel we have made a larger hammer to ease the job. This is hung from the crane as shown above. On this occasion we operated a four man team, one heating (left), two swinging the hammer (centre left and centre right) and the fourth operating the crane to adjust the height (right).

This view shows the job with the heavy work completed. The patches have now been removed to grind the weld preparation for the seal weld onto the side wrapper sheet.

Back to the grind!

News update March 2008

Work has progressed on the foundation ring with some 205 rivet holes reamed along the sides and the back of the firebox. Some 41 holes have been drilled through the new copper tube plate for foundation ring rivets at the front of the firebox and these have also been reamed to size. With the foundation ring in place a further 62 stays have also been fitted. This brings the total number of stays fitted to date up to 1200 including 230 crown stays. Around 100 remain to be fitted most of which can be done once the door plate patches are fitted.

Reaming for foundation ring rivets.

Drilling the foundation ring to accept studs around the corners.

Drill set-up for stud holes.

Tapping the foundation ring ready for the corner studs.

Tapping for the palm stays.

News update Feb 2008

On February 2nd the repaired foundation ring was fitted by the SVR Boiler Shop Foreman and a number of 2857 Society volunteers, ably assisted by a number of Scotchmen.

This view shows the foundation ring in place after a few hours of gentle persuasion.

Over the previous few weeks more work had been carried out on the foundation ring as illustrated in the following photographs. This involved removal of studs on the corners (see detail ‘A’ on Bob Kyte's boiler diagram). These studs fasten the outer wrapper to the foundation ring on the corners as there is only sufficient space for one rivet.

This view shows the stud holes (circled with chalk), the un-marked one is for the single rivet. With all the remnants of stud removed it was clear that remaining threads would be inadequate so the existing holes have been welded up.

Part way through the welding process.

Welding completed, the remaining hole is for the one corner rivet. New holes will be drilled once after the foundation ring has been fitted.

General view taken on the 12 December 2007.

Further work on stays has also been carried out.

The steel stays through the throat plate patch have been riveted over. First the stay is heated with an oxy-acetylene torch.

And then riveted over.

The stay is then caulked to ensure it is steam tight.

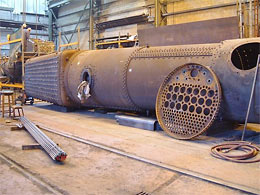

The boiler has been turned recently as shown in this general view taken on the 19th January 2008. With the completion of tube plate and door plate riveting we have been able to fit more side stays.

Another general view of the boiler again taken on the 19th January, this time showing the right hand side of the firebox. The palm stay brackets have now been riveted, some of the rivet heads can just be seen on the boiler barrel immediately in front of the throat plate/barrel seam.

New tender number plate pattern (left) and casting (right). When in service on the SVR the tender ran with the wrong number plate. This has now been rectified with this reproduction plate. Thanks to all involved.

© 2857 Society 2007-2009